Blue Foot Membranes

Booth number: D33

bluefootmembranes.com

About us

We think a little differently. Driven by passion, fuelled by innovation!

Since 2017, Blue Foot Membranes has been redefining water treatment.

Inspired by nature, we provide unbreakable membrane technology that transforms wastewater into reusable safe clean water.

Imagine using Ultrafiltration membranes within Membrane Bioreactors (MBR) which combine the strength of ceramic with the flexibility and experience of polymeric technologies.

That is the Blue Foot solution. Delivering unbreakable membrane technology within numerous applications across the globe.

Our membranes deliver efficient wastewater treatment with higher flux rates, smaller footprint, reduced energy and chemical consumption, delivering the lowest total cost of ownership.

Address

Benzstr. 5

48369 Saerbeck

Germany

E-mail: martin.jansen@bluefootmembranes.com

Phone: +65 9645 1636

Internet: www.bluefootmembranes.com

1 Goldhill Plaza #02-27

308899 Singapore

Singapore

E-mail: martin.jansen@bluefootmembranes.com

Phone: +65 9645 1636

Internet: www.bluefootmembranes.com

Contact person:

Products & Services

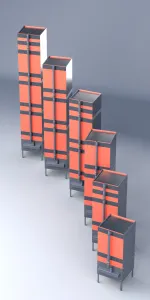

IPC® Flex

- The chosen technology for full scale MBR plant solutions.

- Modular design.

- Stackable up to three modules high, serviced by an integrated aeration box, simplifying installation within a reduced footprint.

- Side-by-side mounting for a compact design.

- In-situ cleaning with the ability to backwash up to 2 bar, reducing chemical consumption and reducing aeration.

- Typical nominal capacity: 1.500 – 3.500 L/h per module.

- Modular design allows for flexibility of deployment, especially for containerised solutions.

- Can retrofit existing MBR with minimal plant alteration required.

IPC® Flex

IPC® Flex:

- The chosen technology for full scale MBR plant solutions.

- Modular design.

- Stackable up to three modules high, serviced by an integrated aeration box, simplifying installation within a reduced footprint.

- Side-by-side mounting for a compact design.

- In-situ cleaning with the ability to backwash up to 2 bar, reducing chemical consumption and reducing aeration.

- Typical nominal capacity: 1.500 – 3.500 L/h per module.

- Modular design allows for flexibility of deployment, especially for containerised solutions.

- Can retrofit existing MBR with minimal plant alteration required.